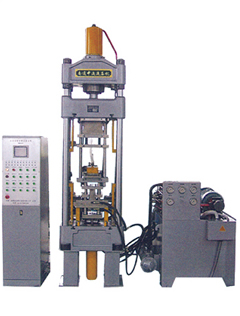

The series Hydraulic Press is used in press forming process of powder products featuring the following characteristics:

●Various external frame: four-pillar, double-pillar, single-pillar, frame model

●Tonnage: 6~630 ton

●Completed control function: manual, semi-automatic, full-automatic, import PLC and touch screen

●Plenty of press technologies: Unique adjustable discharging pressure function, powder precipitated function, alternative two-way press or floating press, equipped hydraulic, frictional and machinery processing, general mold unloading and protection mold unloading, automatic feeding and extraction."

●Stable press precision: up to less than 0.05mm with stroke switch control, machinery limited position and stroke, import grating ruler for limiting position.

●Open control system: press tonnage, speed, stroke, time, pressure, mold unloading form can be adjusted by users

●It can be suitable for the forming of upper three steps and below four steps products at most and equipped with corresponding forming frames.

Main technologic parameter:

|

Parameter |

單位 |

ZY79Z-40 |

ZY79Z-63 |

ZY79Z-100 |

ZY79Z-200 |

ZY79Z-315 |

ZY79Z-500 |

ZY79Z-630 | |

|

Nominal pressure |

KN |

400 |

630 |

1000 |

2000 |

3150 |

5000 |

6300 | |

|

Max work pressure of liquid |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 | |

|

Max distance from slide block to worktable |

mm |

800 |

1000 |

1200 |

1500 |

1700 |

1800 |

2000 | |

|

Slide run parameter |

press force |

KN |

400 |

630 |

1000 |

2000 |

3150 |

5000 |

6300 |

|

Return force |

KN |

180 |

190 |

190 |

450 |

630 |

1000 |

1000 | |

|

Stroke |

mm |

350 |

400 |

600 |

700 |

800 |

900 |

900 | |

|

Quick descent |

mm/s |

60 |

70 |

100 |

100 |

100 |

100 |

100 | |

|

Slow descent |

mm/s |

30 |

25 |

15 |

12 |

12 |

12 |

6 | |

|

Floating press speed |

mm/s |

20 |

20 |

12 |

8 |

10 |

8 |

6 | |

|

Back press speed |

mm/s |

15 |

10 |

10 |

6 |

6 |

6 |

4 | |

|

Return speed |

mm/s |

80 |

100 |

80 |

80 |

75 |

80 |

80 | |

|

Knock out plunger run parameter |

Knockouts Force |

KN |

280 |

280 |

400 |

800 |

1000 |

2000 |

2500 |

|

Down drawing force |

KN |

190 |

190 |

350 |

600 |

800 |

1600 |

2000 | |

|

Stroke |

mm |

150 |

150 |

250 |

250 |

300 |

350 |

350 | |

|

Worktable effective area(Right to left × Front to back ) |

mm |

500× 460 |

580× 490 |

720× 580 |

100× 900 |

1260× 1120 |

1400× 1400 |

1500× 1500 | |

|

Electric Power |

kw |

5.5 |

5.5 |

7.5 |

15 |

15 |

30 |

30 | |

|

Weight |

kg |

2000 |

2500 |

4000 |

12000 |

15000 |

28000 |

34000 | |

|

Max distance from slide block to worktable | |||||||||